How to Calculate Generator Capacity Based on Starting Current – Cummins Engineering Guidelines

Selecting the correct emergency generator capacity is critical for cost efficiency and operational reliability. Unlike standardized methods for transformers, China currently lacks a unified calculation formula for generator sizing, leading to common errors:

Arbitrary selection (10-20% of transformer capacity)

Over-sizing (wasting capital)

Under-sizing (failing during emergencies)

Cummins Engineering Department provides these scientifically validated approaches:

1. Planning/Preliminary Design Phase

Rule of Thumb:

Generator capacity = 10-20% of total transformer capacity

Example: For a 2,000kVA transformer → 200-400kVA generator

2. Detailed Design Phase (Load-Based Calculation)

Classify building loads into three categories:

| Load Type | Examples | Inclusion Criteria |

| Critical (Mandatory) | Fire pumps, emergency lighting, elevators, smoke control systems, data centers | Always include |

| Essential (Conditional) | General lighting, non-emergency elevators, corridor lighting | Include if: • High-availability facility • Unstable grid power |

| Non-Essential | HVAC, general pumps, non-critical equipment | Exclude |

Key Insight

Fire mode: Only critical loads operate

Non-fire blackout: Critical loads are inactive

Never simply sum all loads – this causes 30-50% oversizing

3. Starting Current Considerations

Account for motor inrush currents (typically 6x rated current):

Step 1: List all motors with starting sequence

Step 2: Apply diversity factors:

Simultaneous starts: 1.0

Staggered starts: 0.5-0.7

Step 3: Use formula:

Generator kVA = (ΣRunning Loads + Σ(Starting Current × Diversity Factor)) / 0.8 (PF)

Example:

100kW fire pump (600A starting current)

50kW emergency lighting (no inrush)

Diversity factor: 0.6

Generator kVA = [(50 + 100) + (600 × 0.6)] / 0.8 = (150 + 360) / 0.8 = 637.5kVA → Select **650kVA**

Cummins-Specific Recommendations

For data centers/hospitals: Add 20% margin to calculated capacity

For industrial plants: Use load profiling software (PowerCommand® 4.0)

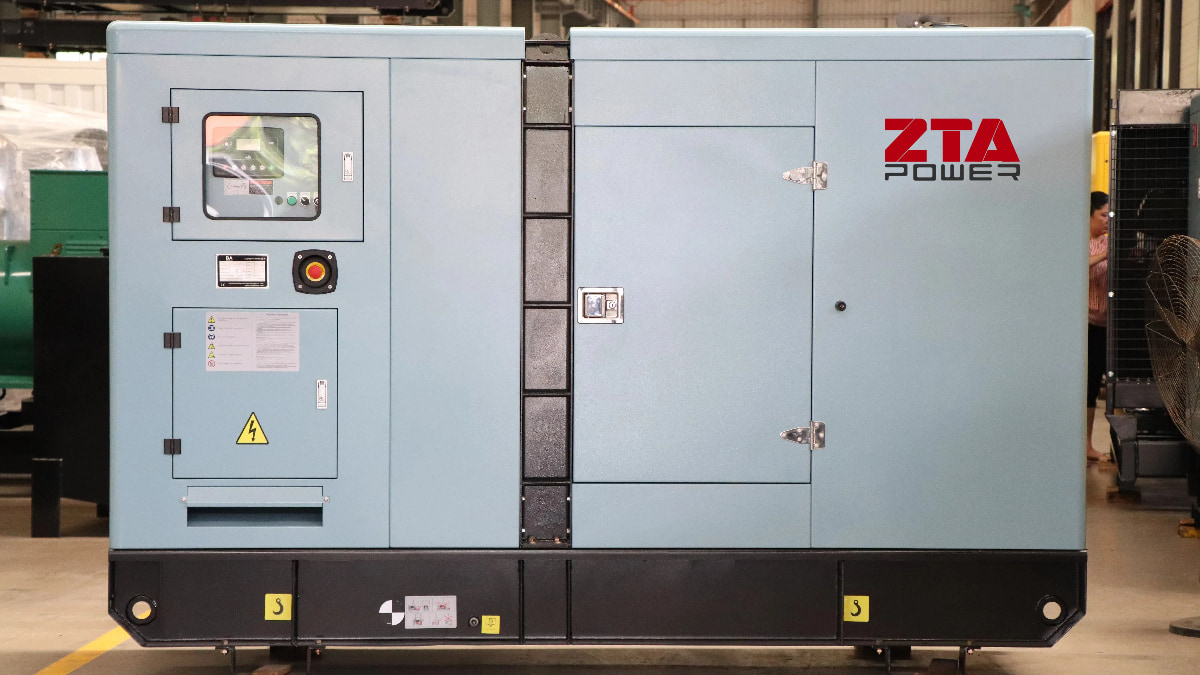

ZTA POWER's Generator Sizing Methodology

For optimal emergency generator capacity selection, ZTA POWER recommends choosing the larger value from the following two calculation methods, incorporating both load diversity and motor starting requirements:

1. Base Load Calculation

Formula:

P=k×PjηP=ηk×Pj

Where:

PP = Generator power (kW)

Pj=Kx×PΣPj=Kx×PΣ (Calculated load)

KxKx: Demand factor (0.85–0.95)

PΣPΣ: Total connected load (kW)

ηη: Parallel operation unbalance factor (0.9 for multiple units, 1 for single)

kk: Safety factor (1.1)

2. Motor Starting Capacity Verification

Method A: Starting kVA Requirement

P=(PΣ−Pm)ηΣ+Pm×K×C×cosψm(kW)P=ηΣ(PΣ−Pm)+Pm×K×C×cosψm(kW)

Parameters:

PmPm: Largest motor/group starting power (kW)

ηΣηΣ: System efficiency (0.85)

cosψmcosψm: Motor starting PF (0.4)

KK: Motor starting current multiple (typically 6–7x)

CC: Starting method coefficient:

Direct-on-line: 1.0

Y-Δ: 0.67

Auto-transformer:

50% tap: 0.25

65% tap: 0.42

80% tap: 0.64

Method B: Voltage Dip Limitation

P=Pn×K×Xd′′×(1ΔE−1)(kW)P=Pn×K×Xd′′×(ΔE1−1)(kW)

Parameters:

Xd′′Xd′′: Generator transient reactance (0.25)

ΔEΔE: Allowable voltage dip:

With elevators: 20%

Without elevators: 25%

Special Case: VFD-Driven Motors

For facilities using variable frequency drives (VFDs)

Starting current drops to 1.5–2x rated current

Voltage dip < 5%

Simplified approach: Ignore starting current; size based on calculated load (PjPj) only

ZTA POWER Recommendations

Industrial Plants: Prioritize Method A (starting kVA) for heavy machinery

Commercial Buildings: Emphasize Method B (voltage stability) for sensitive loads

Hybrid Approach:

Calculate both methods

Select the higher value

Add 10% margin for future expansion

Pro Tip: For mission-critical facilities (hospitals/data centers), conduct transient analysis using software like ETAP.

Always verify with transient response tests (must recover voltage within 2 seconds)